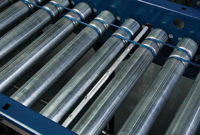

Telemecanique Roller Conveyor Sensors

Shop by Brand

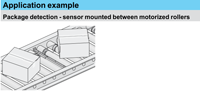

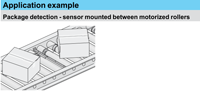

Roller conveyor sensing has never been easier! A sensor that lasts! Perfect for items such as packets, boxes, or letters!

|

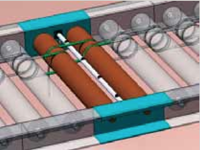

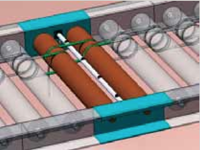

| Telemecanique Sensor’s OsiSenseTM XUY photoelectric sensors are really innovative for fast and smart integration in conveyor systems.Fast, modular & best installation time:

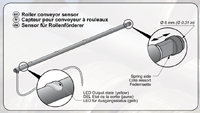

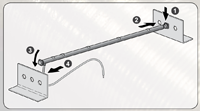

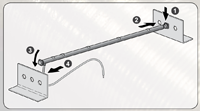

The sensor is mounted between rollers from the top. No more missing screws to mount your bracket and sensor. Plug & Play: to see any package, no color effect, and no environment teaching. Dust protection: special lenses and LED power to avoid dust accumulation Impact resistant: unique mechanical installation embedded within the conveyor frame to prevent product damage |

| Full automation integration: The sensor is compatible with zone controllers from current motorized roller manufacturers or with standard PLC platforms. Different connectors or cable wires are offered. • Typical areas of application: • detection of packet, boxes, pallets and letters of paper, carton or metallic material • Well suited for use in: • conveying for manufacturing facilities, warehouses, and retail distribution centers |

| Watch a video and see first hand how easy the XUY Roller Conveyor Sensor is to mount and operate –

https://www.youtube.com/watch?v=h3h4Y9Efzuk |

| Benefits • Fast and simple installation: • No tools needed • Easy mounting from the top • Gain of 50% in installation and adjustment • 3 mounting solutions (Hexagonal 7/16”, Ø 8 mm, or adhesive supports) Full detection : • No package color effecting sensor performance due to reliable infra-red sensing technology • Easy direction adjustment, every 30° • Full length detection from multiple sensors embedded within the sensor housing • Convex lens to avoid dust accumulation |

|

|

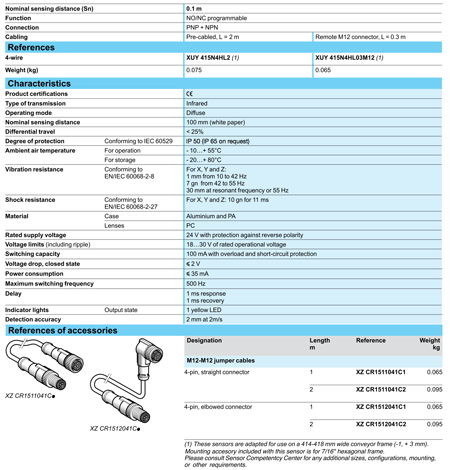

| Product Specification |

|

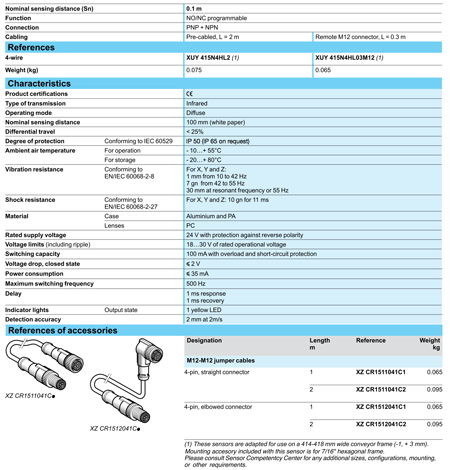

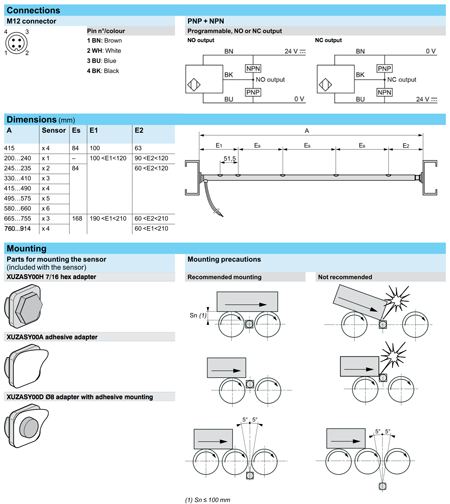

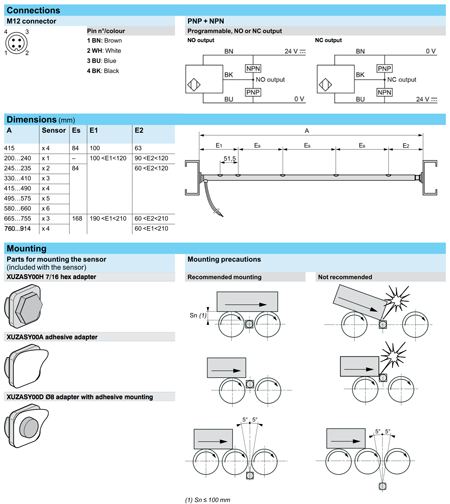

| OsiSenseTM XUY XUY415N4HL2 XUY415N4HL03M12Mechanical Caracteristics: Dimension (width) Number of sensors Diameter (case) Sensor pitch Connection Mounting Material Case LensDetection performances: Detection mode Nominal sensing distance Minimum object size Maximum flow rateElectrical Caracteristics: Voltage limits Current consumption Output LED Switching capacity Switching frequencyEnvironmental characteristics: Operating temperature IP class |

| Roller conveyor sensor PNP/NPN, NO/NC by cabling cable 2m or remote M12 connector415 mm, from 200 to 914 upon request 4 (number of sensors is determined by the overall conveyor width) 12mm 84 mm M12 4 pins connector or cable Hexagonal 7/16”, Ø 8mm or adhesive Aluminium and PA PCDiffuse infrared 100 mm 85 mm 60 m/mn18 to 36 Volts DC (including ripples) 35 mA yellow 100 mA with overload and short circuit protection 500 Hz-10°C to 50°C IP50 (IP65 upon request) |

| XUY Roller Conveyor Sensor |

|

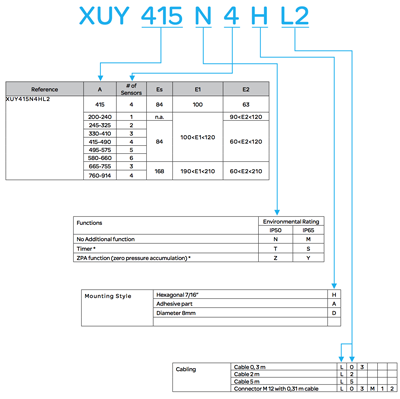

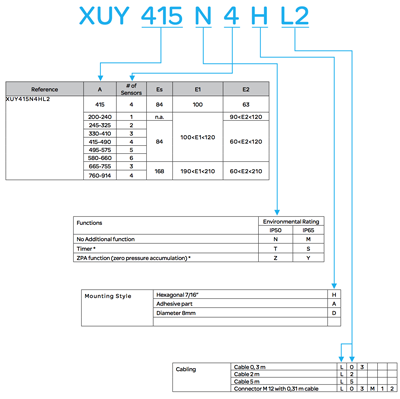

| Catalog Number Configuration |

|

| For this example, XUY415.. is available for any conveyor width from 414 to 418 mm (-1, +3 mm) * Future capability. Call local field sales office for more information and availability. Important Note: Not all configurations may be possible. |

| Photo-electric sensors OsiSense XU Application, conveying series For detecting packages on a roller conveyor DC supply, solid-state output |

|

|

|

|

No products were found matching your selection.